Pronar MPP 1238s Scalper Screen

- Autonomous tracked drive system

- Impact bars in hoppers and oversized conveyors

- Auto-start system equipped

- Individually controlled belt drives

Product Overview

This powerful machine, with two decks, precisely separates materials into three fraction sizes. Touchscreen-adjustable speeds and easily adjustable screening box inclination enable seamless fine-tuning for specific material types. The 136 HP 3.6-liter engine efficiently handles heavy loads without high revolutions. The vibrating box lifting system and side tensioning of decks ensure quick access and a brief setup.

24 Month / 2000 Hour Limited Warranty.

About the Screenbox

- Metal plate at the beginning of the box to prevent damaging screening media with big rocks

- Easy tensioning of both top and bottom deck

- Removable bottom deck or whole side conveyor for two-way split conversion

- Fixed catwalk on both sides for easy access

Applications

This product can be used for the following applications:

Features & Advantages

Transportable Advantage

The scalper screen operates with a fully autonomous drive, guaranteeing smooth and uninterrupted functionality. Its design allows for exceptional mobility, enabling it to be effortlessly repositioned around the worksite without the need for additional towing gear. Thanks to its tracked chassis, the machine can be easily moved to reach challenging or hard-to-access areas.

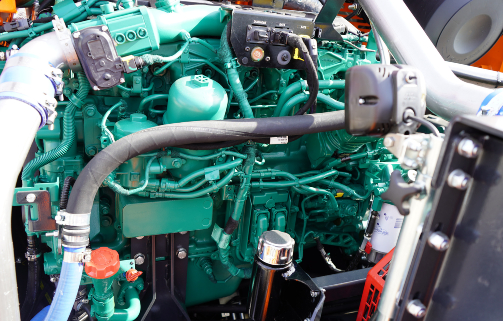

Powerful Engine

This powerful machine requires significant energy to achieve peak performance. It can be fitted with a Caterpillar 3.6L, 90 kW (122 HP) Stage V/Tier 4 Final engine, a Deutz 3.6L, 90 kW (122 HP) Stage V/Tier 4 Final engine, or a Caterpillar 3.6L, 90 kW (122 HP) Stage 3A engine. The latest environmentally friendly technologies have been incorporated into these engines to meet the most up-to-date emissions regulations.

Material Separation

This powerful machine, with two decks, precisely separates materials into three fraction sizes. Touchscreen-adjustable speeds and easily adjustable screening box inclination enable seamless fine-tuning for specific material types. The 136 HP 3.6-liter engine efficiently handles heavy loads without high revolutions. The vibrating box lifting system and side tensioning of decks ensure quick access and a brief setup.

User-Friendly Controls

Using this powerful machine is surprisingly straightforward and doesn’t need extensive training. The remote control streamlines key functions, which is especially useful for managing the hopper tipping grid. For manual operation, the machine features an easy-to-use control panel that is conveniently placed. There’s also a rear control panel for secure and effortless adjustment, setup, and unfolding of the conveyor.

Superior Screenbox

The design of the screening box includes a metal plate at the entrance to protect the screening media from damage caused by large rocks. It features an easy tensioning system for both the top and bottom decks, ensuring optimal performance. The bottom deck or entire side conveyor can be removed for a straightforward two-way split conversion. Additionally, fixed catwalks on both sides of the machine provide convenient access for maintenance and operation.

Durability & Efficiency

The Pronar MPP 1238s scalper screen is engineered for high-efficiency material handling with its impressive conveyor system. It features an oversized 40" conveyor for handling larger volumes and bulky materials with ease. Complementing this is the 35" transfer conveyor, designed to smoothly move material from the oversized conveyor to other processing stages. Additionally, the mid-size 31.5" conveyor ensures effective handling of intermediate material flows, providing a well-balanced and efficient screening process. Together, these conveyors enhance the scalper screen’s capability to manage and process diverse material sizes effectively.

US Dollars

US Dollars