Screenpod AT1500 Windsifter

- Dual 11kW High Energy Blower Fans

- Air Recirculation System

- Wide Infeed Conveyor

- Large Separation Drum

Product Overview

Unlock exceptional separation capabilities with the Screenpod AT1500 Windsifter, revolutionizing material waste stream processing. This versatile windsifter seamlessly integrates into any materials processing operation, offering high throughput with customizable settings for various applications. Experience significantly accelerated recycling rates, potentially replacing manual sorting methods entirely. Extract greater material volumes, enhance product quality, reduce landfill-bound waste, and create new revenue streams – all from a user-friendly package with minimal maintenance requirements.

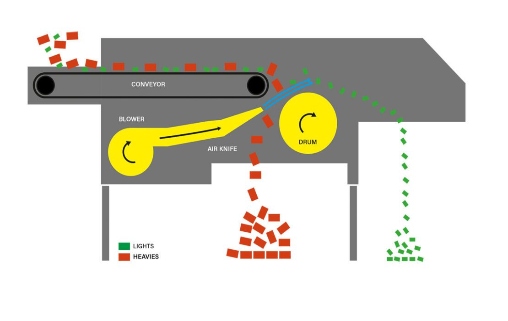

The AT1500 Windsifter excels in separating lightweight ('lights') and heavyweight ('heavies') materials within a given material stream. The mixed material is fed onto the infeed conveyor, accelerating towards the discharge point while evenly spreading across the conveyor width.

Upon reaching the end of the conveyor, the material drops onto a rotating drum. Simultaneously, an 'Air-Knife' releases a powerful jet of air through the material. Connected to robust blower fans, the Air-Knife's wide and narrow outlet spans the full infeed conveyor width, creating an air stream that passes through the falling material.

In this process, the 'lights' are carried away in the airstream, effectively separated from the 'heavies,' which drop straight down. The 'heavies' can be directed into a skip, storage area, or conveyed to the machine's side via an optional side conveyor. Simultaneously, the 'lights' can be collected in a skip or storage area, or fed into another machine for further processing.

Improve your material processing efficiency with the Screenpod AT1500 Windsifter – a comprehensive solution designed for enhanced recycling rates and versatile material separation.

Applications

This product can be used for the following applications:

Features & Advantages

Dual 11kW High-Energy Blower Fans

These powerful fans generate a robust air stream, effectively separating lightweight materials from heavier ones, thus improving the purity of the output.

Air Recirculation System

This system reduces dust emissions and minimizes energy consumption by recirculating air within the machine, promoting a cleaner and more sustainable operation.

Wide Infeed Conveyor with Variable Speed and Adjustable Angle

The conveyor accommodates a broad range of material sizes and types, with adjustable speed and angle to ensure consistent and efficient feeding into the separation chamber.

Large Separation Drum

The spacious drum enhances the separation process by providing ample space for materials to be sorted accurately, increasing throughput and efficiency.

On-Board Electrical Control Panel

This integrated control panel offers user-friendly operation and precise adjustments, allowing operators to fine-tune settings for optimal performance across different materials.

Infinitely Variable Infeed System

This feature enables continuous adjustment of material feed rates, ensuring a steady flow and preventing blockages, which enhances overall operational efficiency.

US Dollars

US Dollars